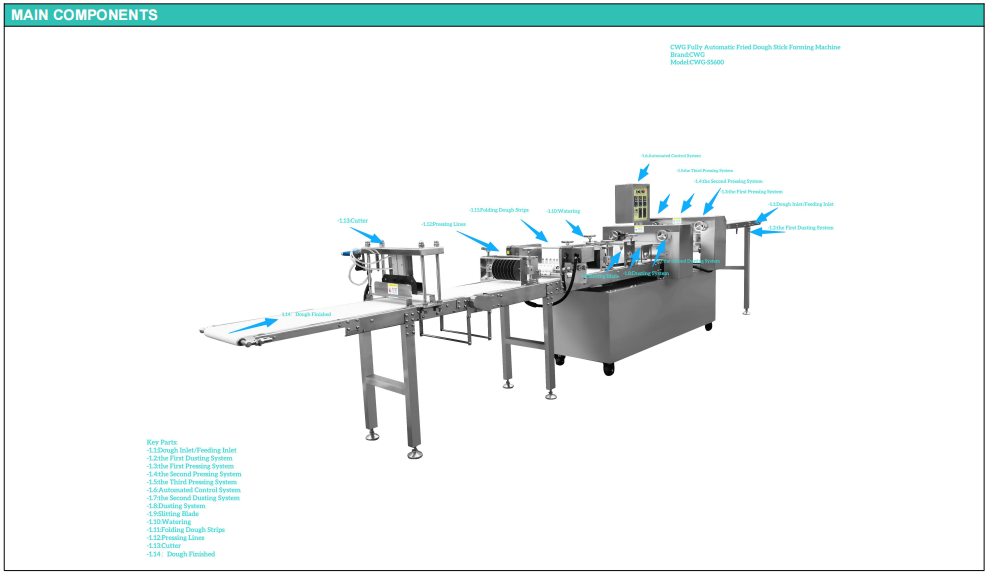

■Definition:

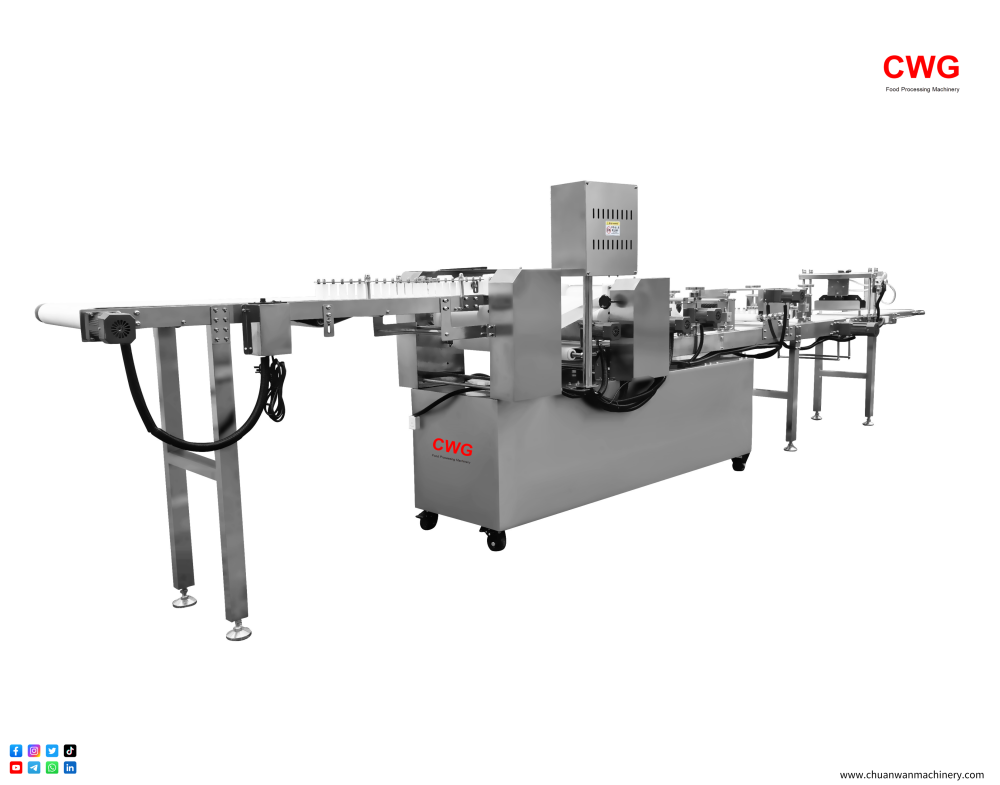

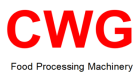

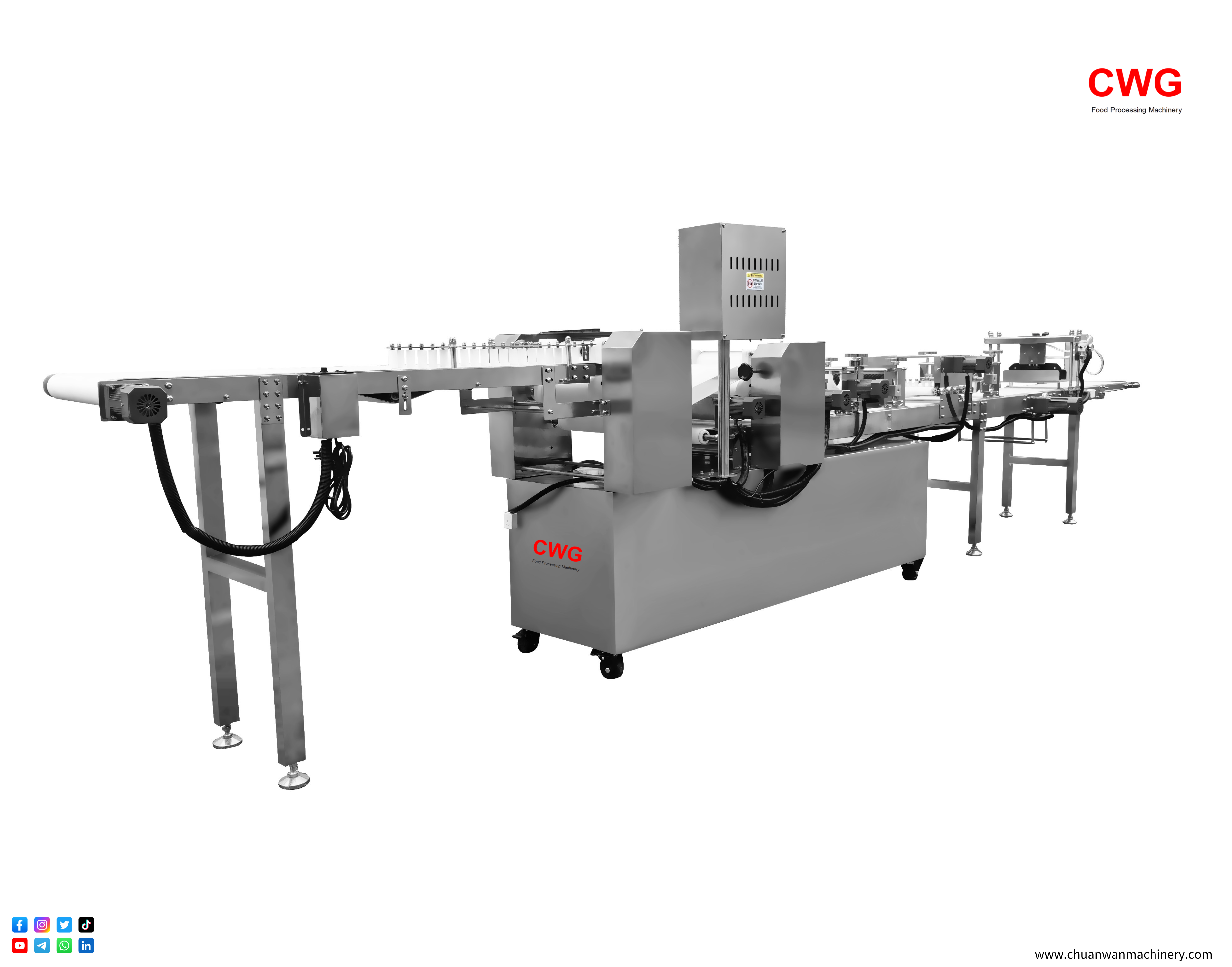

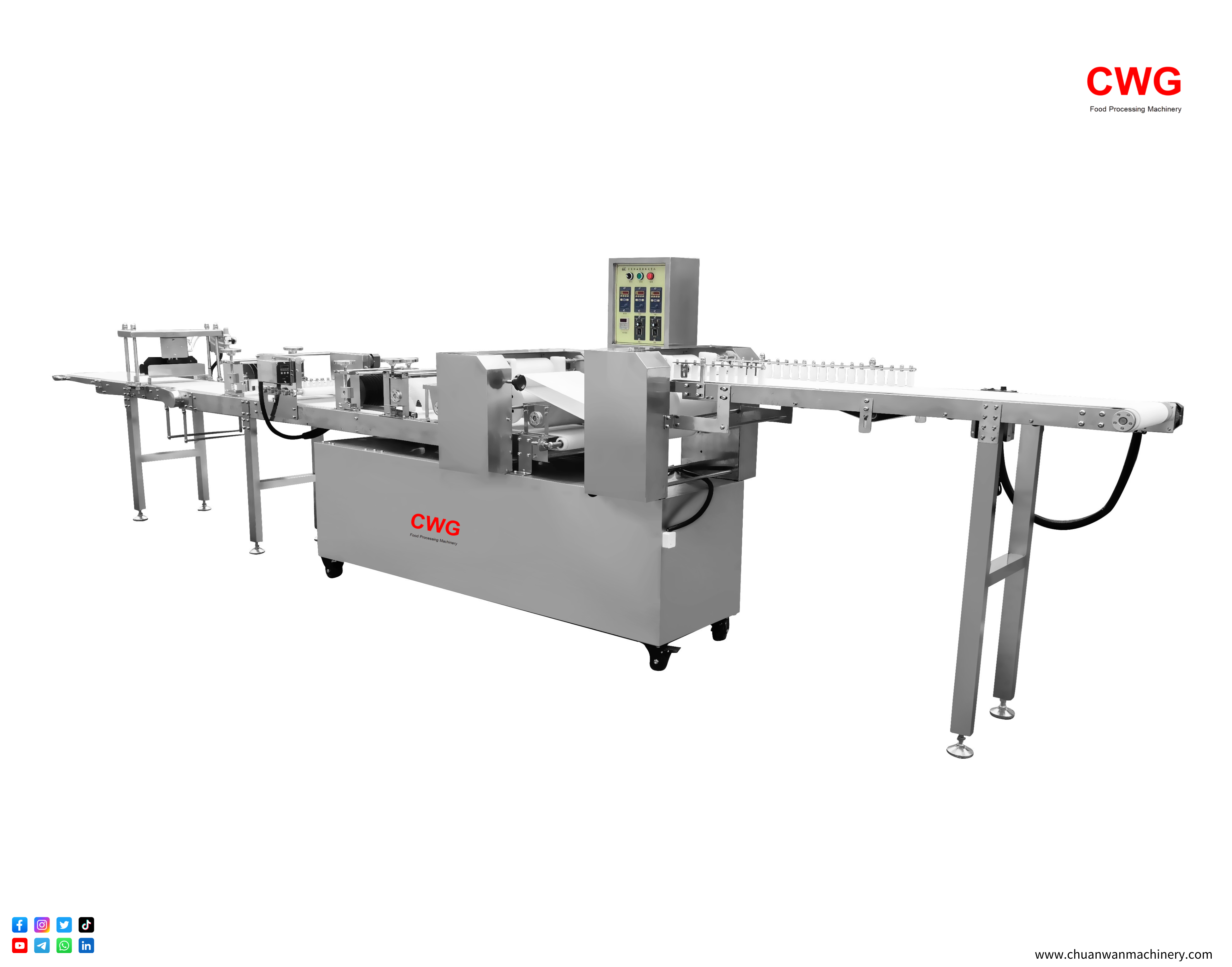

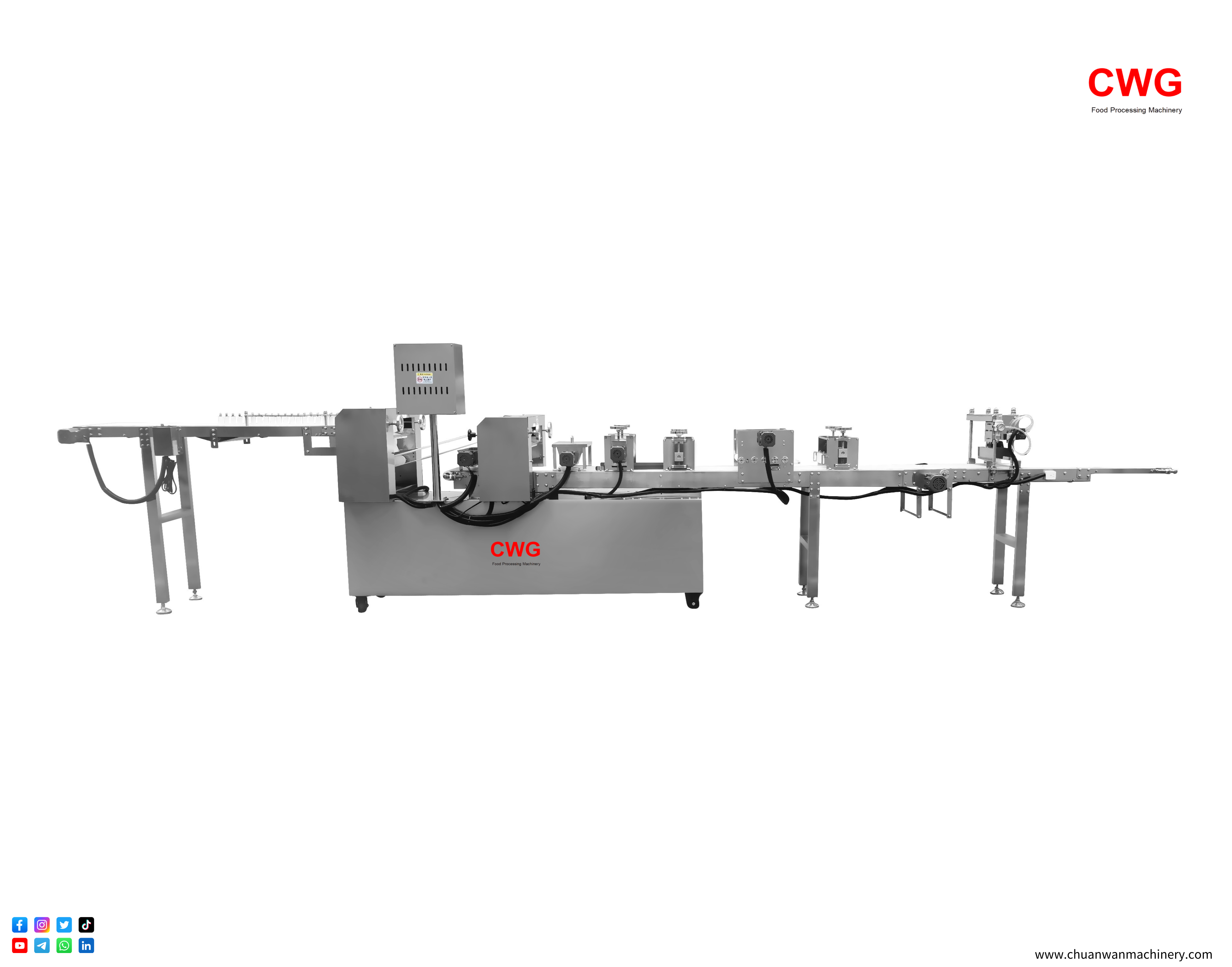

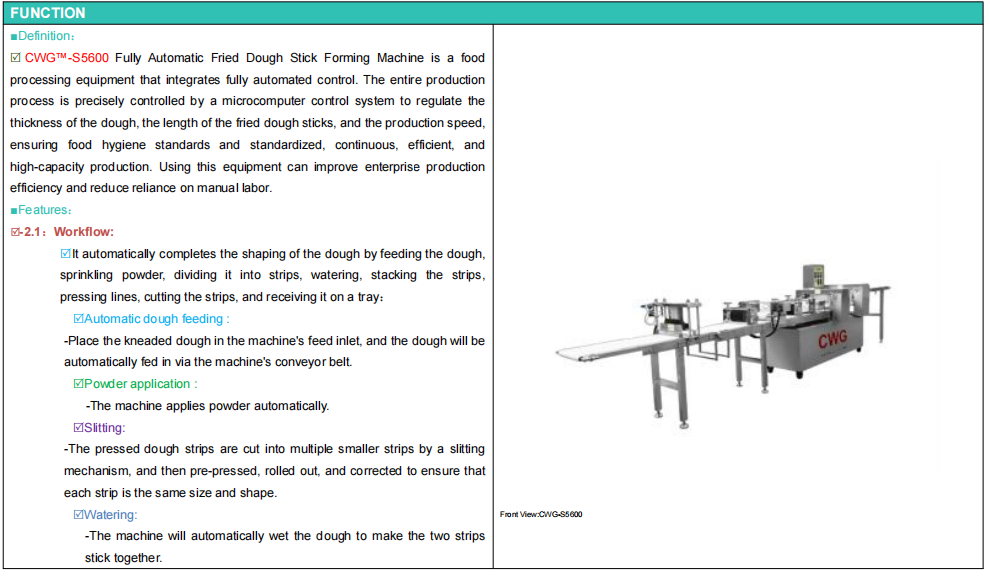

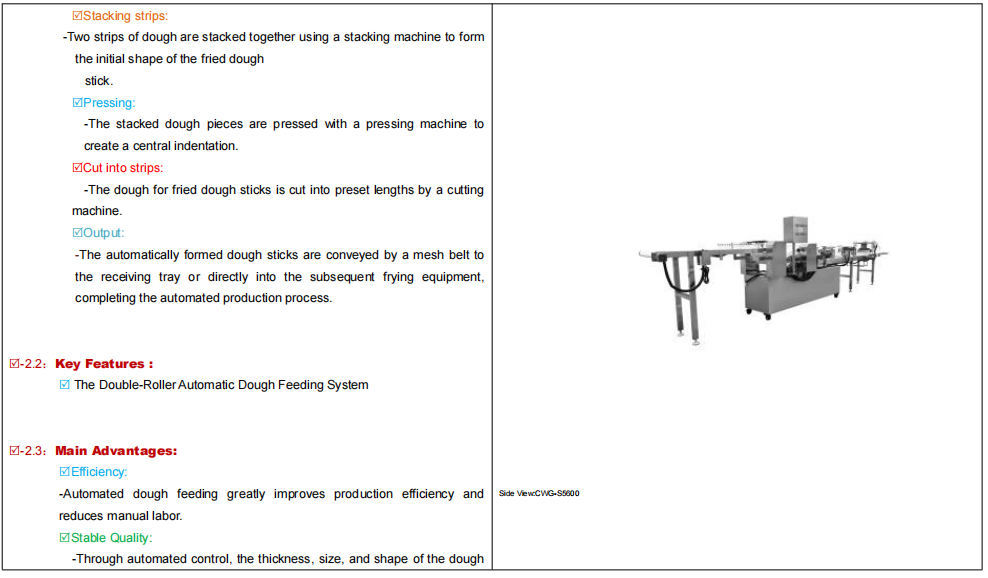

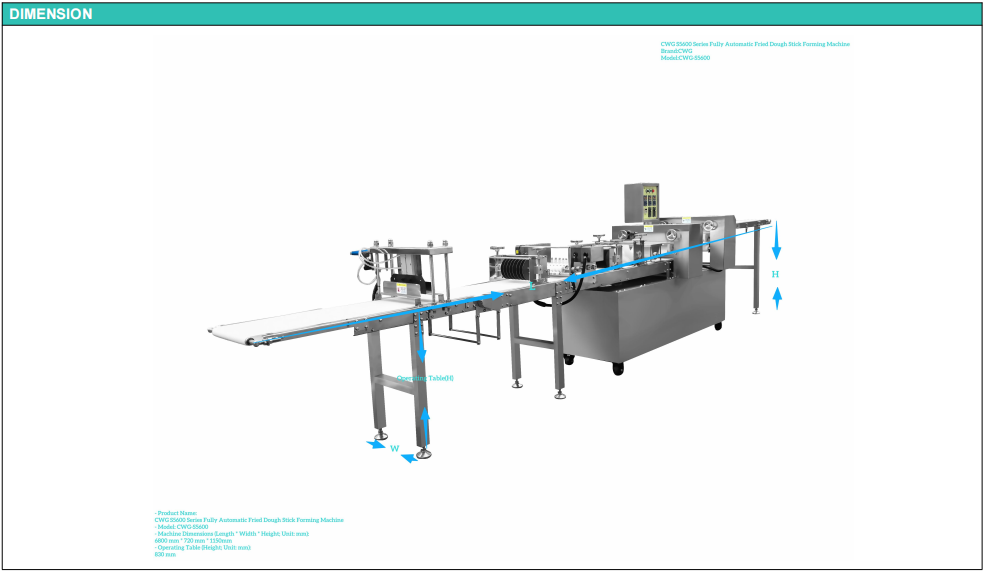

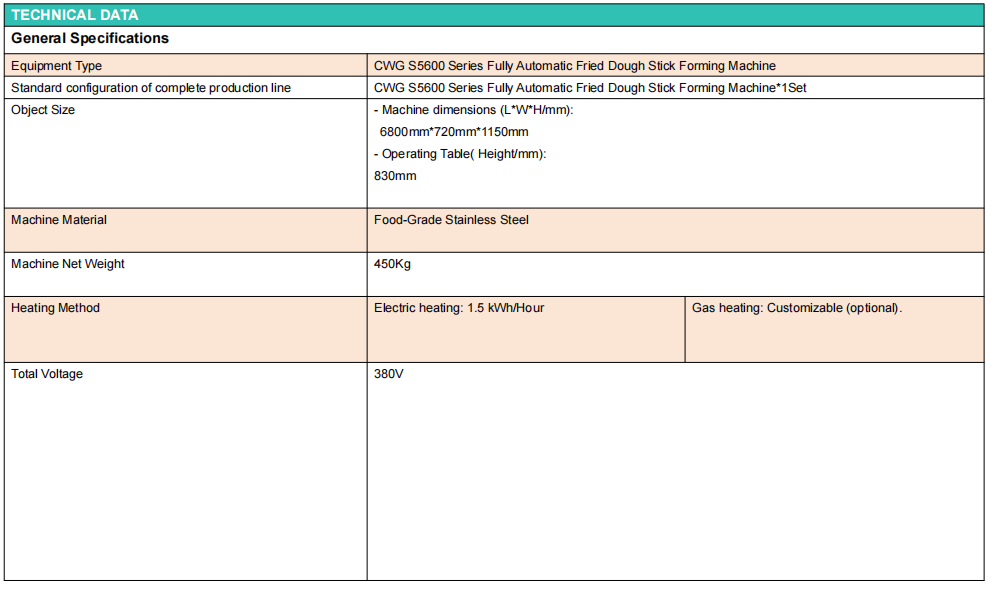

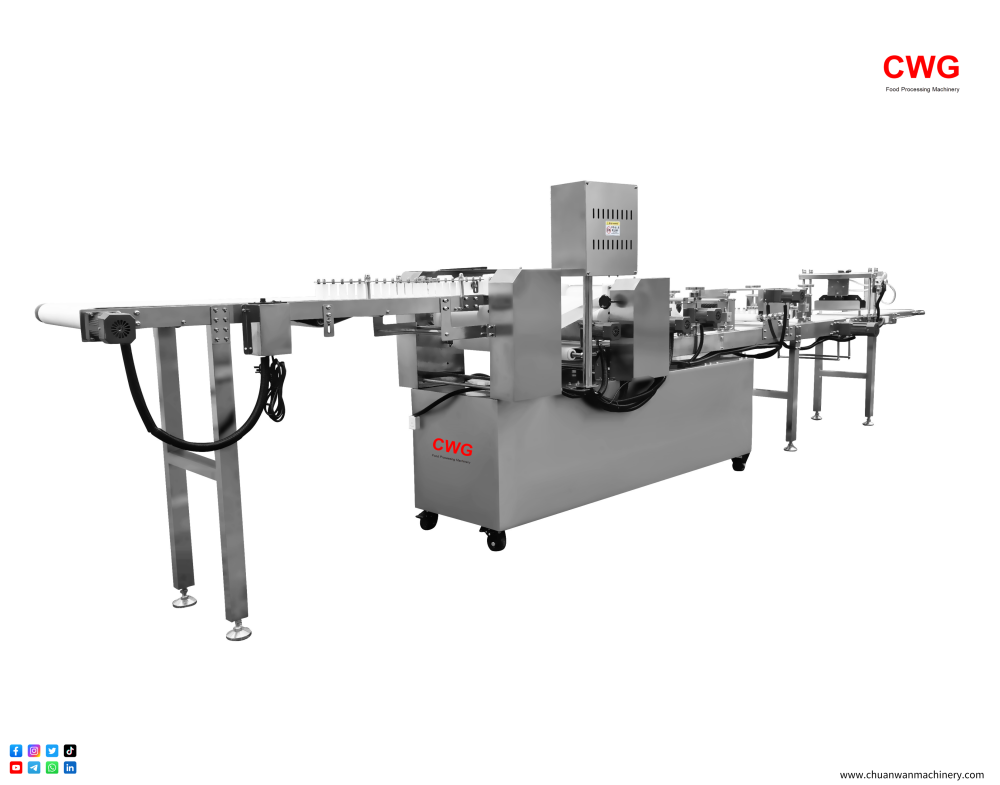

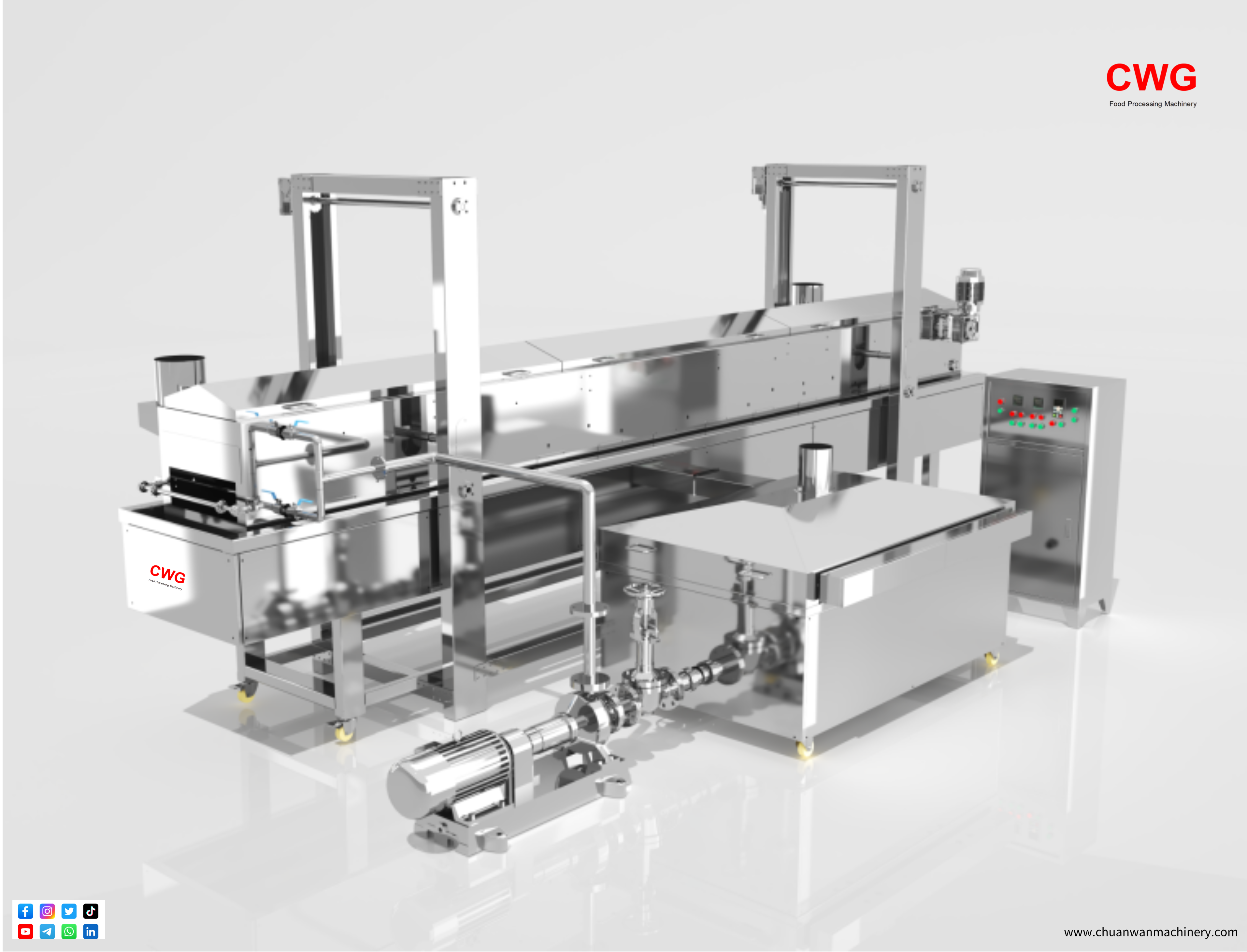

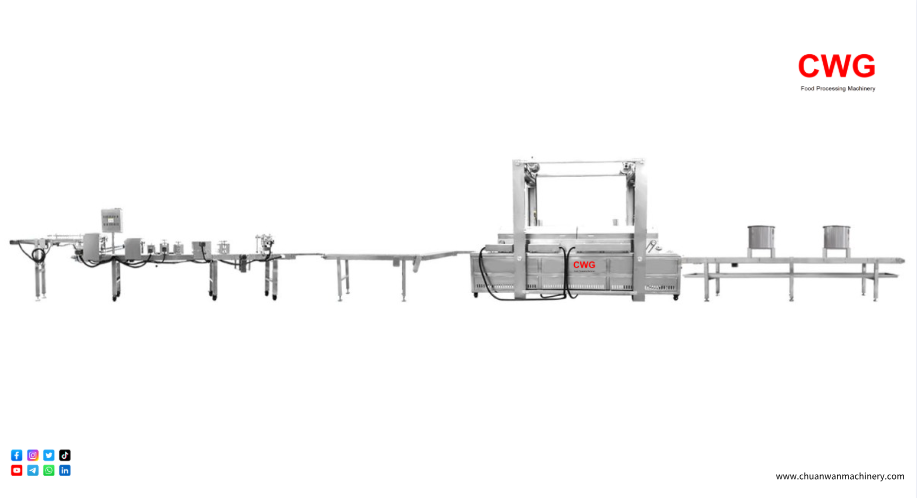

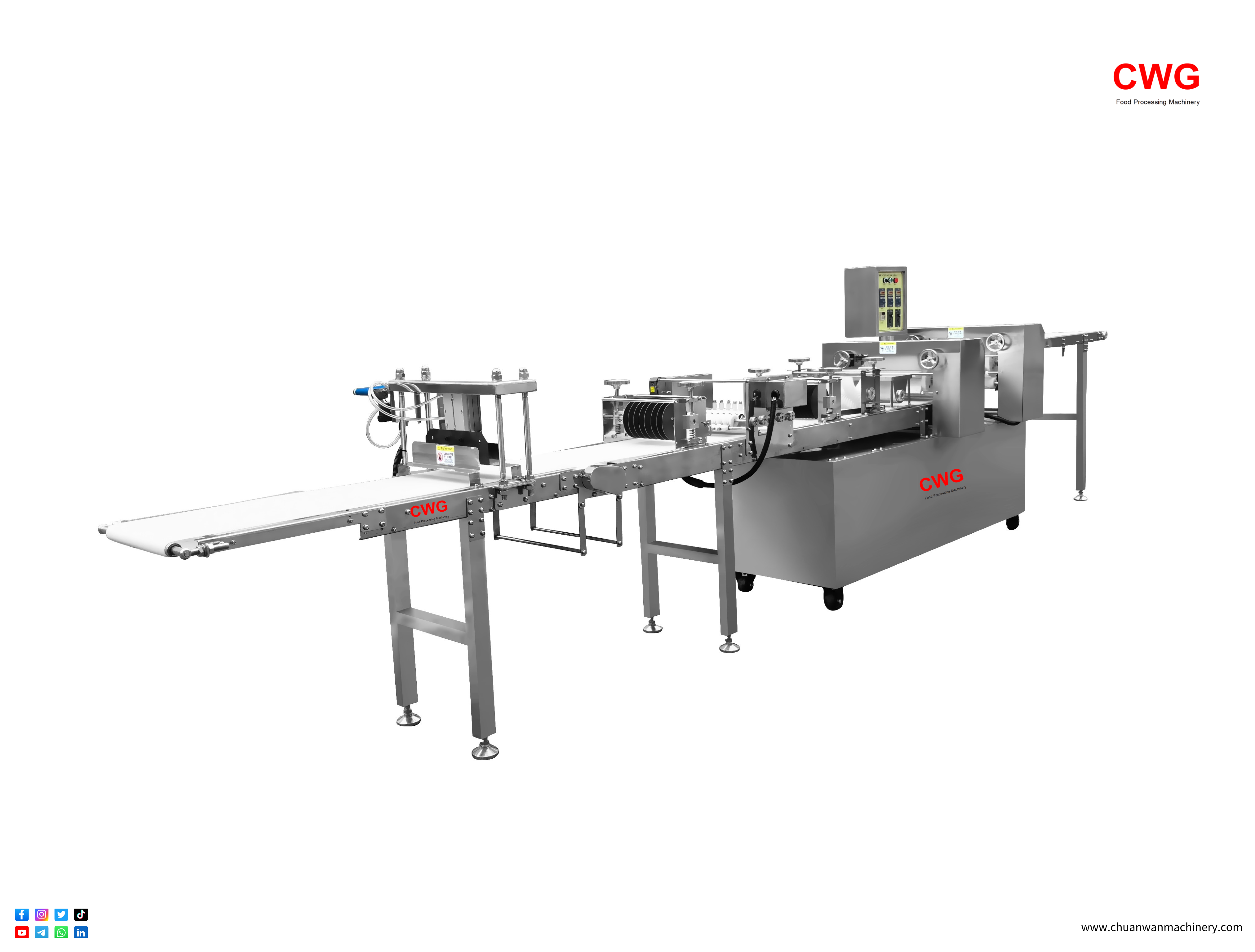

CWG™-S5600 Fully Automatic Fried Dough Stick Forming Machine is a food processing equipment that integrates fully automated control. The entire production process is precisely controlled by a microcomputer control system to regulate the thickness of the dough, the length of the fried dough sticks, and the production speed, ensuring food hygiene standards and standardized, continuous, efficient, and high-capacity production. Using this equipment can improve enterprise production efficiency and reduce reliance on manual labor

■Features:

–2.1:Workflow:

It automatically completes the shaping of the dough by feeding the dough, sprinkling powder, dividing it into strips, watering, stacking the strips, pressing lines, cutting the strips, and receiving it on a tray:

- Automatic dough feeding :

-Place the kneaded dough in the machine’s feed inlet, and the dough will be automatically fed in via the machine’s conveyor belt.

-The machine applies powder automatically.

-The pressed dough strips are cut into multiple smaller strips by a slitting mechanism, and then pre-pressed, rolled out, and corrected to ensure that each strip is the same size and shape.

-The machine will automatically wet the dough to make the two strips stick together.

-Two strips of dough are stacked together using a stacking machine to form the initial shape of the fried dough

stick.

-The stacked dough pieces are pressed with a pressing machine to create a central indentation.

-The dough for fried dough sticks is cut into preset lengths by a cutting machine.

-The automatically formed dough sticks are conveyed by a mesh belt to the receiving tray or directly into the subsequent frying equipment, completing the automated production process.

-2.2:Key Features :

- The Double-Roller Automatic Dough Feeding System

-2.3:Main Advantages:

-Automated dough feeding greatly improves production efficiency and reduces manual labor.

-Through automated control, the thickness, size, and shape of the dough are more uniform and stable.

-Reduces labor costs and losses during the production process.

■Industry&Food Applications:

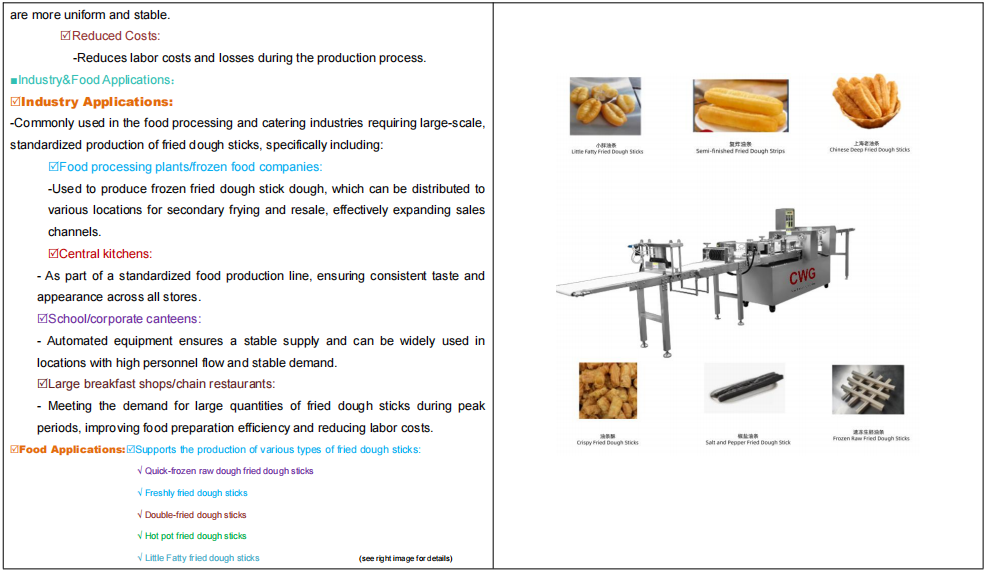

-Commonly used in the food processing and catering industries requiring large-scale, standardized production of fried dough sticks, specifically including:

- Food processing plants/frozen food companies:

-Used to produce frozen fried dough stick dough, which can be distributed to various locations for secondary frying and resale, effectively expanding sales channels.

– As part of a standardized food production line, ensuring consistent taste and appearance across all stores.

- School/corporate canteens:

– Automated equipment ensures a stable supply and can be widely used in locations with high personnel flow and stable demand.

- Large breakfast shops/chain restaurants:

– Meeting the demand for large quantities of fried dough sticks during peak periods, improving food preparation efficiency and reducing labor costs.

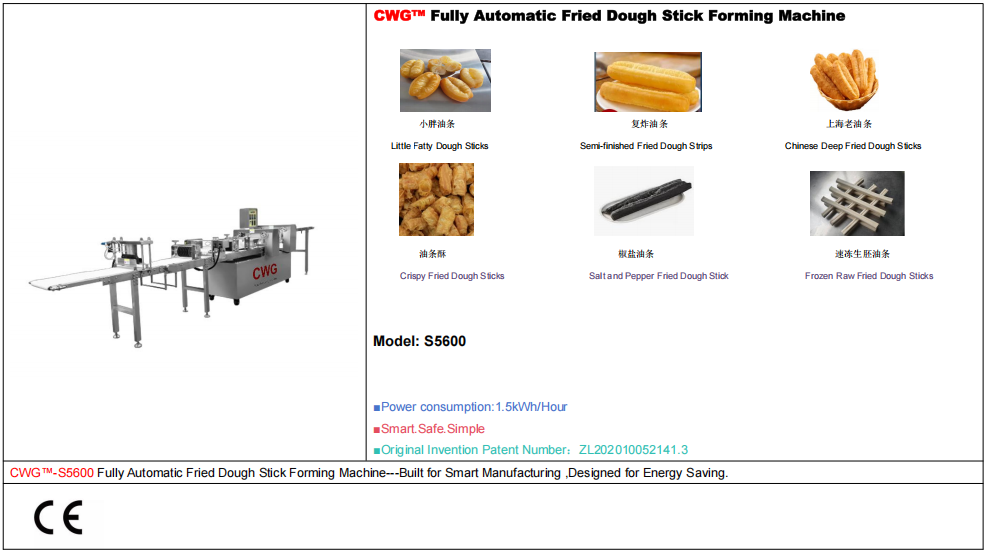

Food Applications:

Supports the production of various types of fried dough sticks:

√ Quick-frozen raw dough fried dough sticks

√ Freshly fried dough sticks

√ Double-fried dough sticks

√ Hot pot fried dough sticks

√ Little Fatty fried dough sticks (see the image for details)